Patented Reprogrammable Photomasks

Maximize Flexibility for Complex Projects

Digitho’s reprogrammable photomasks enable rapid pattern adjustments across wafers, accommodating multi-product wafers and allowing precise tuning for analog devices in sophisticated projects.

Accelerate Development Cycles Cost-Effectively

Achieve faster development with affordable, rapid iterations using the same systems as full-scale production.

This approach reduces costs while maintaining high quality and regulatory compliance.

Lower Masking Costs with Precision

Digitho’s i-line reprogrammable photomask provides a cost-effective way to print non-critical features while preserving overlay accuracy and alignment, meeting exacting standards.

Enhance Yield with Adaptive Patterning

Our adaptive patterning efficiently routes between chiplets in dense layouts, ensuring high yields and optimal performance for multi-chiplet, high-frequency devices, even with slight misplacements.

Secure Your Supply Chain

Digitho’s serialization solution leverages reprogrammable masks for secure chip traceability, enabling precise wafer mapping based on performance, deterring counterfeiting, and ensuring industry compliance.

Effortless Traceability for Complex Chiplet Packages

Digitho delivers seamless traceability for advanced packaging and chiplet markets, providing a non-disruptive solution ideally suited for high-volume manufacturing.

Solutions

Secured Cloud Platform for semiconductor Supply Chain Traceability

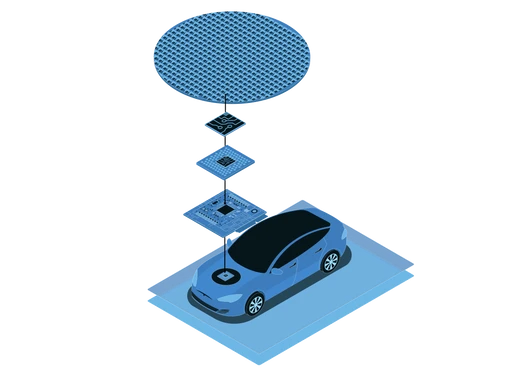

Innovative Photolithography Solution

Resources

Identification with a Datamatrix on Each Die

Root Cause Analysis & Recalls

Unit Level Traceability at the Die Level

Success Stories

Digital Lithography vs. Maskless Lithography: Choosing the Right Approach for Your Semiconductor Manufacturing Process

In this article, we will explore the differences, benefits, and considerations of digital lithography and maskless lithography to help operations directors make informed decisions about

How Chiplets Revolutionized the Semiconductor Industry

The semiconductor industry has experienced a remarkable revolution thanks to a recent innovation called “chiplets.” These small, standalone integrated circuit units have transformed the way

Enhancing Automotive Supply Chain Traceability with SOC Solutions

In the fast-paced and highly complex automotive industry, maintaining a robust and transparent supply chain is crucial for success. Traceability plays a vital role in

Our Partners